RECOMMENDED INSTALLATION FOR PEBBLE TILES

NOTE: this contains only guidelines for the installation process. A professional installer should always be consulted to discuss the specific parameters surrounding your project. The installer should follow TCNA guidelines for installation.

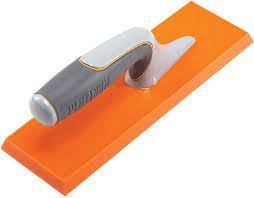

TOOLS REQUIRED

PebbleTile.co decorative Pebbles can be used in an extensive range of design applications, internally and externally. Applications include foyers, bathrooms, fountains, water features, pools, driveways, pathways, kitchens, feature walls, fireplaces and entertainment areas. During manufacturing, pebbles are hand sorted into matching colors and sizes and individually glued onto a mesh backing. As pebbles are a natural product, no two pieces will be exactly alike. It is not unusual to find occasional flaws, veins, and lines of separation within the pebbles. This variation is considered to be a desired feature in the product.

CURVED SURFACES

Decorative Pebble mosaics can be installed around gently curved surfaces. Some manipulation of the tiles may be required in order to create uniformity between each sheet.

SUBSTRATES

All substrates should be firmly fixed, flat, clean, dry and free of contaminants such as dust, oil, paint, sealers etc. To ensure proper adhesion. Painted surfaces must be scuffed or sanded for the product and adhesive to bond correctly. Wet areas need special attention and require appropriate substrates, e.g. concrete, cement boards (compressed sheet), and/or treated plywood. The use of reinforced waterproof membranes is suggested, and in the case of floors, a fall to the drainage point of no less than two inches.

WATERPROOF MEMBRANES

Waterproof membranes prevent leakage of water through to the sub-floor framing and/or habitable spaces below. Particular attention must be paid to: carrying the membrane up the wall, outside shower boxes, installation of bond breakers, and sealing around penetrations. It is strongly recommended that membrane systems be used in all wet areas. Some systems may involve the use of a primer.

CUTTING

Cuts can be done with either a wet saw or a hand grinder with a masonry blade. The mesh back can be easily cut with a utility knife. Some pebbles may need to be removed and replaced by hand to make the installation look more seamless. For certain applications cuts may not be necessary. As there are no straight lines in the product, when approaching a straight edge the last row of pebbles can be removed from the mesh and adjusted by hand.

ADHESIVE

Follow the adhesive manufacturer’s instructions carefully. We do not recommend one brand of adhesive over another. Please check with your local tile supply store for alternative and comparable products. The manufacturer's literature will explain if the adhesive product is suitable for interiors and/or exteriors, as well as walls and floors. Most thinset mortars (multi purpose and polymer modified thinsets) are adequate for installing pebbles. A cement-based adhesive is generally suitable on masonry substrates where no movement is anticipated. Where slight movement could occur through thermal or pedestrian loads, a modified cement adhesive should be used as a minimum. A notch trowel 5 mm is recommended for most applications.

The use of a gray thinset mortar may be desired if you are using the dark pebbles, and a white thinset for lighter colors. It is very important that each pebble is embedded in the adhesive. To make sure there is 100% coverage, tap the sheets into the adhesive gently with a rubber float and try to avoid having the thinset come up from in between the pebbles.

GROUTING

Grout should be suitable for joints up to 20 mm in width and designed for external or internal conditions whichever may be the case. Sanded grout is generally recommended for any grout joint larger than 5 mm. Grouts are ordinarily a water mix but where some flexibility may be needed, a latex additive or similar product should be used. It is important to wait the interval recommended by the adhesive manufacturer before grouting to minimize dirt ingress between the pebbles and avoid the opportunity for dislodging of the pebbles. In the event that one desires to better expose the pebbles, it is suggested that during the grouting process, the installer repeatedly removes the excess grout from the joints by the use of a medium bristle brush and sponge. During this process, it is also recommended that, if necessary, the excess grout is carved from the edge of the pebbles by use of an appropriate knife.

SEALANTS

To bring your application to its full potential, we suggest sealing BEFORE and AFTER grouting. There are various products available on the market, however, we recommend contacting your nearest tile supplier for the most appropriate sealer for your application. You can change the look and color of the stones depending on the sealer you select ranging from color enhancement, to different levels of gloss finishes, or just leaving them natural. Whenever using sealants and acids, please ensure that you follow the manufacturer’s recommended method of application.

CARE & CLEANING

PebbleTile.Co Decorative Pebble mosaics must be regularly cleaned and maintained to extend the life and beauty of the tile. The pebbles can be cleaned with a neutral mild detergent. The porosity or water absorption in pebbles varies and therefore staining will occur in different degrees if the stone is left unsealed. Consequently, any spills should be cleaned quickly to lessen the degree of the stain. PH neutral cleaners for natural stones are highly recommended. Do not use abrasive cleaners, powders, scouring pads, steel wool or sandpaper.